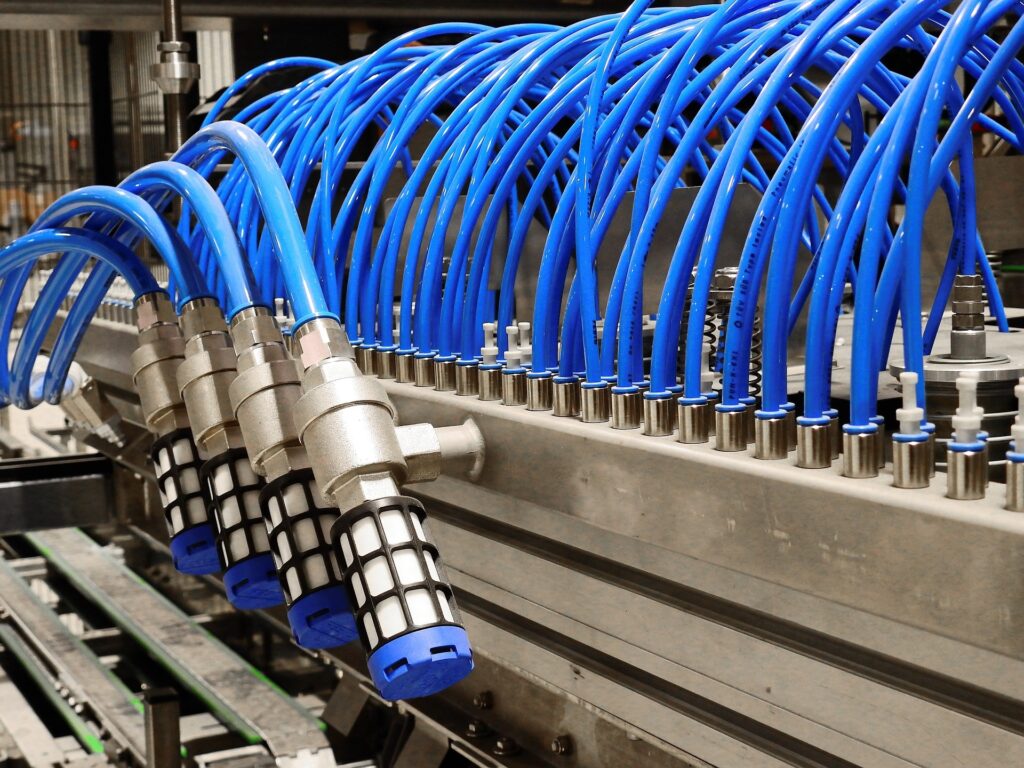

Pneumatics, a branch of engineering that utilizes compressed air or gas to create mechanical motion, has become an essential force driving change in modern manufacturing. Its growing presence across various industries, from automotive to food processing, reflects the ongoing evolution of industrial practices. Pneumatics offers numerous advantages over traditional hydraulic and mechanical systems, making it an appealing choice for manufacturers seeking efficiency, precision, and sustainability. One of the primary benefits of pneumatic systems is their simplicity. Comprising fewer parts compared to hydraulic systems, pneumatics rely on air as their power source, which is readily available and easy to manipulate. This simplicity not only reduces the cost of installation and maintenance but also enhances reliability. Since pneumatic components are less prone to wear and tear, they are more durable, requiring fewer repairs and replacements. This translates into reduced downtime, a critical factor in industries where constant production is key to profitability. Moreover, pneumatic systems are highly adaptable, making them ideal for use in diverse applications.

Whether it is operating a conveyor belt, controlling valves, or powering robotic arms, pneumatics can be easily integrated into existing processes. They offer smooth, precise control, which is vital in manufacturing sectors where accuracy is critical. For instance, in the electronics industry, pneumatic actuators are used to perform delicate tasks such as component placement with minimal margin for error. Their ability to provide consistent, repeatable motion ensures high-quality output, which is crucial in maintaining production standards. Energy efficiency is another significant advantage of pneumatic systems and get more info pneumatig.eu. While hydraulics rely on oil, which can be costly and environmentally harmful, pneumatics operates on air, a renewable and non-polluting resource. This makes pneumatic systems not only eco-friendly but also cost-effective in the long run. As industries increasingly prioritize sustainability, pneumatics aligns with global trends aimed at reducing carbon footprints and minimizing energy consumption. Additionally, advances in pneumatic technology have led to the development of more energy-efficient compressors and components, further enhancing their environmental benefits.

Safety is another critical factor driving the adoption of pneumatics distributor in modern manufacturing. Pneumatic systems operate at lower pressures compared to hydraulics, making them safer to use in environments where high-force operations are required. In the event of a malfunction, pneumatic systems are less likely to cause catastrophic damage or pose risks to workers. This makes them a preferred option in sectors such as food and beverage production, where maintaining a clean and safe working environment is paramount. As industries embrace smart technologies and the Internet of Things IoT, pneumatic systems are being integrated with sensors, controllers, and data analytics platforms. This allows manufacturers to monitor and optimize their operations in real time, leading to greater efficiency and productivity. Pneumatics’ compatibility with these technologies ensures that they remain a relevant and valuable component of modern manufacturing ecosystems. In conclusion, pneumatics is playing a pivotal role in driving change in modern manufacturing by offering a cost-effective, adaptable, and environmentally friendly solution.