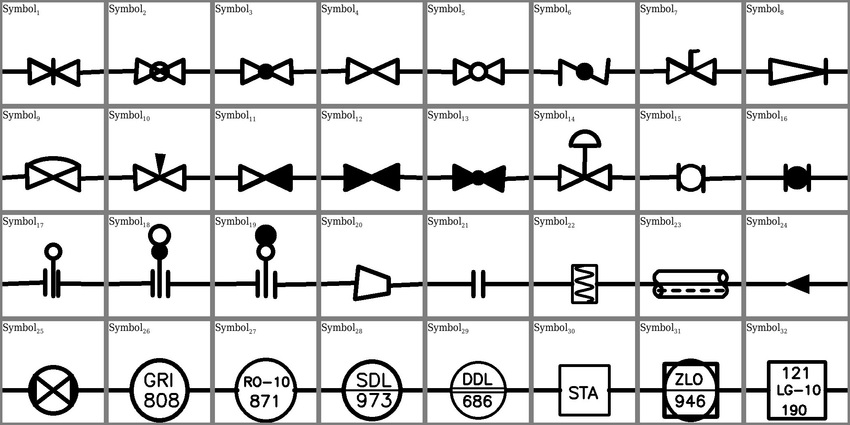

P&ID Piping and Instrumentation Diagram symbols are a crucial part of the engineering and design process, particularly in industries like oil and gas, chemical manufacturing, power plants, and water treatment. These diagrams provide a graphical representation of the physical equipment, piping, and instrumentation that make up a system, and the symbols used within them are standardized to ensure clarity and consistency across various teams and stages of the project. By using P&ID symbols, engineering teams, including mechanical, electrical, instrumentation, and control engineers, can effectively communicate complex system designs and functionality with minimal room for misunderstanding. One of the primary functions of P&ID symbols is to simplify communication. The use of universal symbols for equipment, valves, piping, instrumentation, and control systems means that all members of the project team, whether they are designing, constructing, or maintaining a system, can quickly understand the technical details of a plant or process. A pump symbol on a P&ID immediately conveys its function in the system, whether it is designed to move fluids or gases.

Similarly, symbols for flow control devices, such as valves and regulators, allow engineers to understand how fluids are being managed and directed throughout the system. This visual language is especially useful in a multidisciplinary team, where professionals from diverse backgrounds need to collaborate effectively. P&ID symbols also play a vital role in ensuring safety and compliance with regulatory standards. By using standardized symbols, engineers can quickly identify potential hazards, such as high-pressure systems, toxic chemical lines, or emergency shutoff valves, and ensure that safety protocols are in place. For example, symbols indicating pressure relief devices or emergency shutdown systems are critical for the safe operation of complex industrial facilities. In addition to identifying safety-critical elements, these diagrams help in risk assessment and the identification of system vulnerabilities, ensuring that engineering teams can take proactive measures during the design phase to mitigate potential issues. Moreover, P&ID symbols are indispensable in the operation and maintenance phase of a system’s life cycle.

Once the system is installed, the P&ID diagrams serve as a reference for troubleshooting and maintaining the equipment. Operators and technicians can use these diagrams to identify which instruments control specific parts of the system, how the system components are interconnected, and where to isolate certain sections of the plant for repairs or upgrades. This reduces the likelihood of errors during maintenance activities and minimizes downtime, as maintenance teams can act quickly and precisely. The clarity provided by p&id symbols also enhances documentation and traceability. As projects often involve multiple stages, including conceptual design, detailed design, installation, and operation, having a standardized set of symbols ensures that each team is working with the same set of information. The consistency of symbols across different phases of the project helps engineers track design changes, updates, and modifications over time. This consistency is crucial not only for internal communication but also for regulatory inspections and audits, where accurate and detailed documentation is required to demonstrate compliance with industry standards.